Cylinder Testing |

|

|

Under Spanish law (Real Decreto 366/2005), cylinders are due for visual inspection every year, and a hydrostatic test every three years. This applies to both steel and aluminium cylinders. All cylinders must display a valid test sticker and the paperwork for the cylinder should be retained in case of inspection. Tests may only be undertaken by premises licensed with Industria. Read more about the law in Spain for tank testing here (article 13 refers to the inspection dates).

The fine for out of date cylinders can be high and cylinders may also be confiscated if the cylinder tests are not in date. This includes new cylinders - make sure you have the paperwork, a stamp on the neck is not enough and the test date will be the date on the neck of the cylinder, not the date you bought it. |

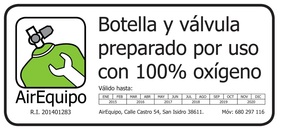

AirEquipo and Paul Sturgess are fully licensed with Industria, Registration Number 23064. Our stamp pictured on the right) is registered with the Spanish Government - you can find a list of registered inspection centres here. Remember, if you choose to use a company which is not legally registered with Industria, then your inspections will not be valid. Paul is also trained by ASSET (Association of Scuba Service Engineers & Technicians) in the UK and AirEquipo is a member of the highly regarded organisation.

|